$55,500.00

100 in stock

Description

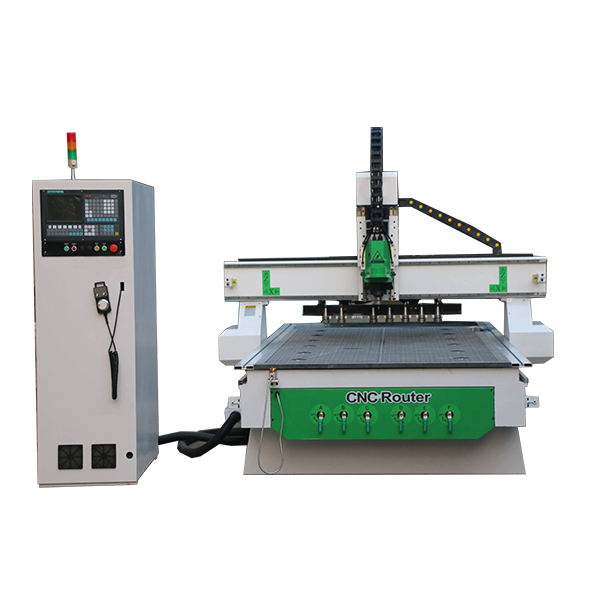

- Brand Name: CORDURAC

- Model Number: INM1530-ATC

- Condition: New

- CNC or Not: CNC

- name: 1530 wood atc cnc router

- Working area: 1500*3000mm

- Control ststem: syntec control system

- Hiwin guide rail: XYZ axis

- Transmission: taiwan reducer

- Motor and driver: yaskawa servo system

- Spindle: HSD 9.0kw ATC air cooling spindle

- accessory parts: water pump, tools

- Table: T-slot& Vacuum table with pump

Chinese factory 1530 wood atc cnc router for kitchen furniture, wood door cnc router

Details of atc cnc router

Main Features of ATC CNC router

1).This atc cnc router machine adopt Italy HSD automatic tool changer spindle makes machine with high precision , long service time and stable movement.

2)Configured with Linear tool magazine of 8tools the machine can change tools speedy and freely. Changing tools in 5 seconds.

3).Vacuum worktable in European standard are used in this atc router table cnc for carpentry, positioning cylinder can be added which make material positoning easily and fast.

4).With high-performance Japan YASKAWA servo motor, the Machine can work in high precision.The servo motor runs smoothly,no vibration phenomenon even in the low speed.And it has a strong ability of overload.

5).Syntec controller—enabling this product to accomplish multi-layer 3D job, cutting, engraving, milling, all at ease.

6). Z axises adopt Taiwan TBI ball screw transmission, X/Y/Z axis adopt Taiwan Hiwin square rail high precision, the structure is more stable.

7)Delta inverter,is one of the best inverter over the world,in addition to the advantage of Fuling inverter, the life time ofDelta inverter is more longer and it can guarantee higher precision.

Performance Parameter of ATC CNC router

| Number | Description | Parameter |

| 1 | X,Y,Z Working Area | 1300mmx2500mmx250mm//1500*3000*250mm |

| 2 | Table Size | 1330mm×3040mm |

| 3 | X,Y,Z Traveling Positioning Accuracy | ±0.03/300 |

| 4 | X,Y,Z Repositioning Accuracy | ±0.03mm |

| 5 | Table Surface | Vacuum and T-slot Combined (Option: T-slot table) |

| 6 | Frame | Welded structure |

| 7 | X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| 8 | Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| 9 | Max. Power Consumption | 4.5kw (Without Spindle) |

| 10 | Max. Rapid Travel Rate | 45000mm/min |

| 11 | Max. Working Speed | 30000mm/min |

| 12 | Spindle Power | 9.0 kw |

| 13 | Spindle Speed | 0-18000RPM |

| 14 | Drive Motors | Yaskawa servo motor |

| 15 | Working Voltage | AC 380V/50/60Hz,3PH |

| 16 | Command Language | G Code |

| 17 | Operating System | Syntec Control System |

| 18 | Computer Interface | Ethernet, CF Card |

| 19 | Flash Memory | 512M(U Disk) |

| 20 | Collet | ER32 |

| 21 | X,Y Resolution | <0.03mm |

| 22 | Software Compatibility | Type3/UcancameV9 software (Option: Artcam software) |

| 23 | Running Environment Temperature | 0 – 45 Centigrade |

| 24 | Relative Humidity | 30% – 75% |

| 25 | Packing Size | 3500X2250X2200mm |

| 26 | N.W. | 1800KG |

| 27 | G.W. | 2000KG |

Please kindly note the above configuration is standard configuration.

Custom Made/ODM/OEM

is available. Just tell us your requirement, we will build the machine accordingly.

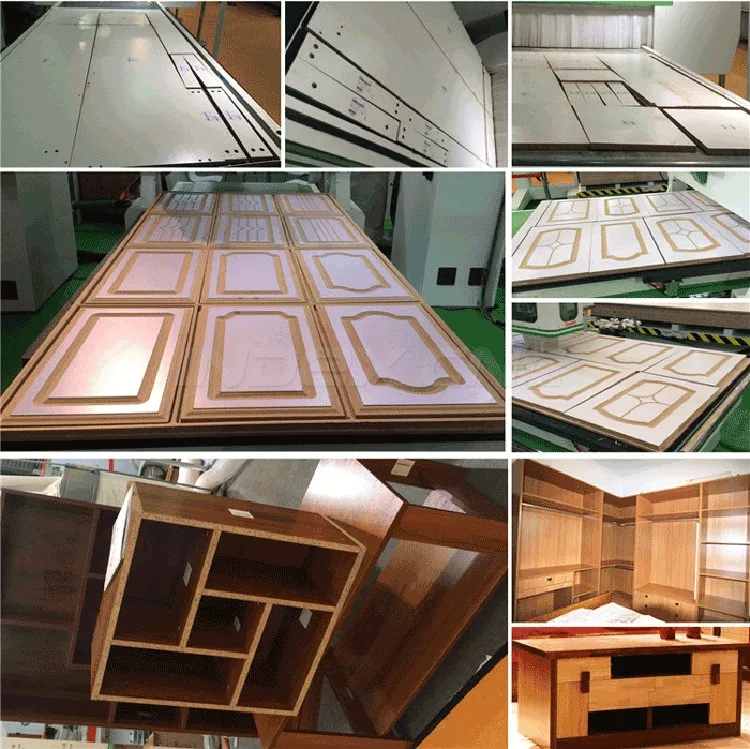

Application of atc cnc router

1. Wood processing: processing density board, stiletto for surfing board, processing of marbles, cabinet and furniture.

2. Advertisement:engraving and cutting of various labels and number plate, marble, etc for artistic effects on materials including marble, brass, steel, and other metallic material.

3. Crafts: engraving characters of any language and patterns on gifts and souvenirs, primitive processing and shaping of artistic crafts, and stiletto.

4. Molding: engraving delicate letter and flower pattern, primitive and fine processing of the small mould.

5. Architectural models: engraving fine window, fencing and wall patterns, etc.

6. Seal: engraving seals and medal on materials such as buffalo horn, wood etc.

7. Label: engraving character, number, and other pattern on label for products and on product directly.

CNC Router technical support:

1. Technical support by phone, email or WhatsApp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

After sales services:

12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free.

Out of 12 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime.

Normal machine is properly adjusted before dispatch. You will be able to use the machine immediately after received machine.

Besides, you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel etc

Before You Buy A CNC Machine – Frequently Asked Questions (FAQ):

1. What’s the difference between a stepper and servo motor?

The basic difference between a stepper and a servo-based system is the type of motor and how it is controlled. In a servo-based system, there is constant signal feedback from the encoder (or motor) to the servo drive. This feedback tells the servo drive exactly where it is within its move. Thus, the servo drive can adjust its power output, as needed, to complete the move. The servo is much more powerful, has quicker acceleration time and quicker positioning speed.

2. How do I hold down my material?

The size of your part, type of material and production goals will determine the most-suitable method of holding your material in place. Generally, a vacuum system is the most-efficient method of holding down your material. You can also mechanically fixture your material with clamps, screws or double-stick tape.

3.Do I need a vacuum hold down system?

A vacuum system is a great addition to any machine. If used correctly a vacuum system can save you time and produce a clean cut edge even on hard to cut material like melamine and acrylic. If you are in a production setting, a vacuum system is a must. It will pay for itself..no questions asked.

Contact INDEXCNC