$56,700.03

99 in stock

Description

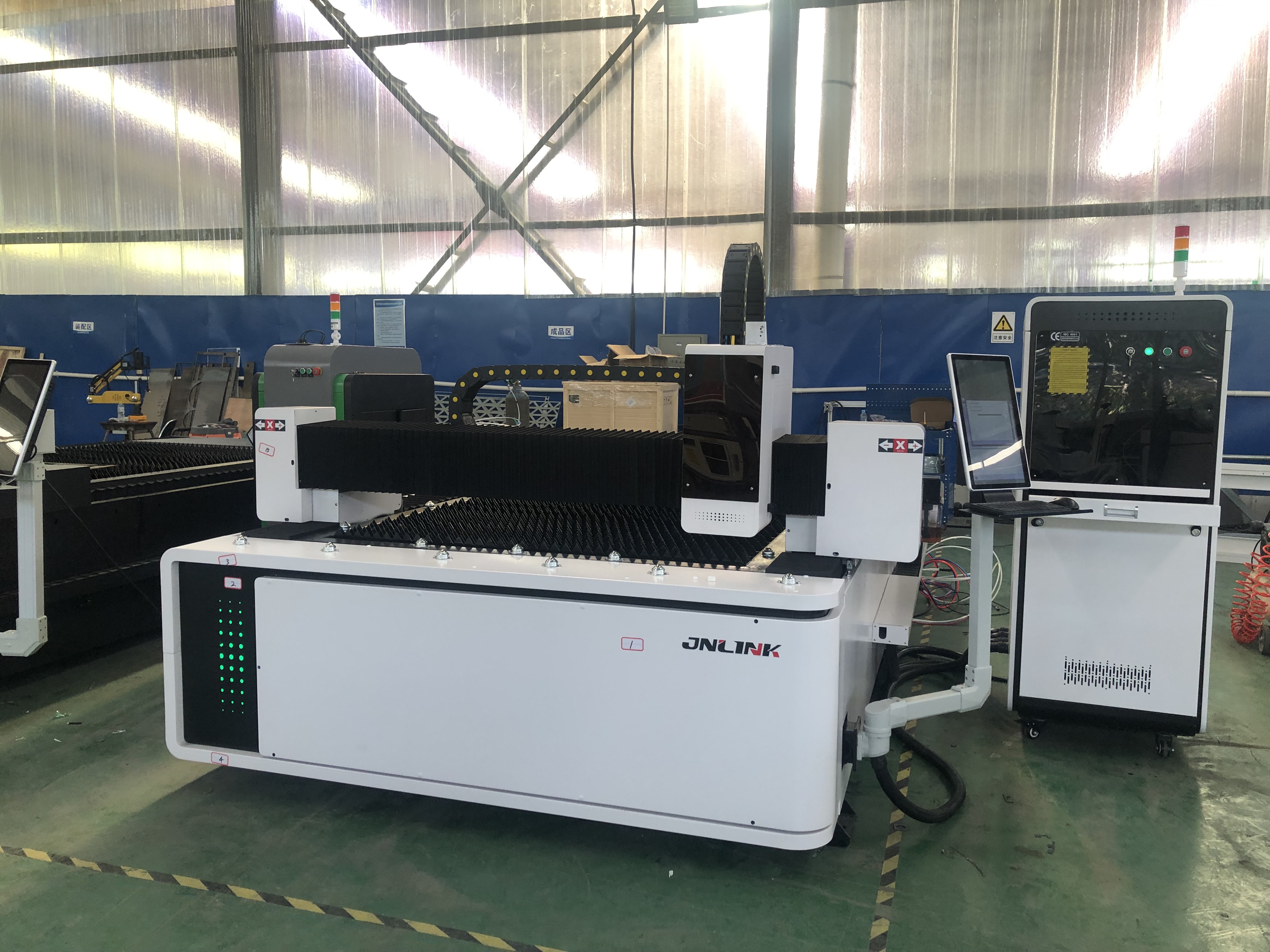

- Brand Name: JNLINK

- Condition: New

- CNC or Not: CNC

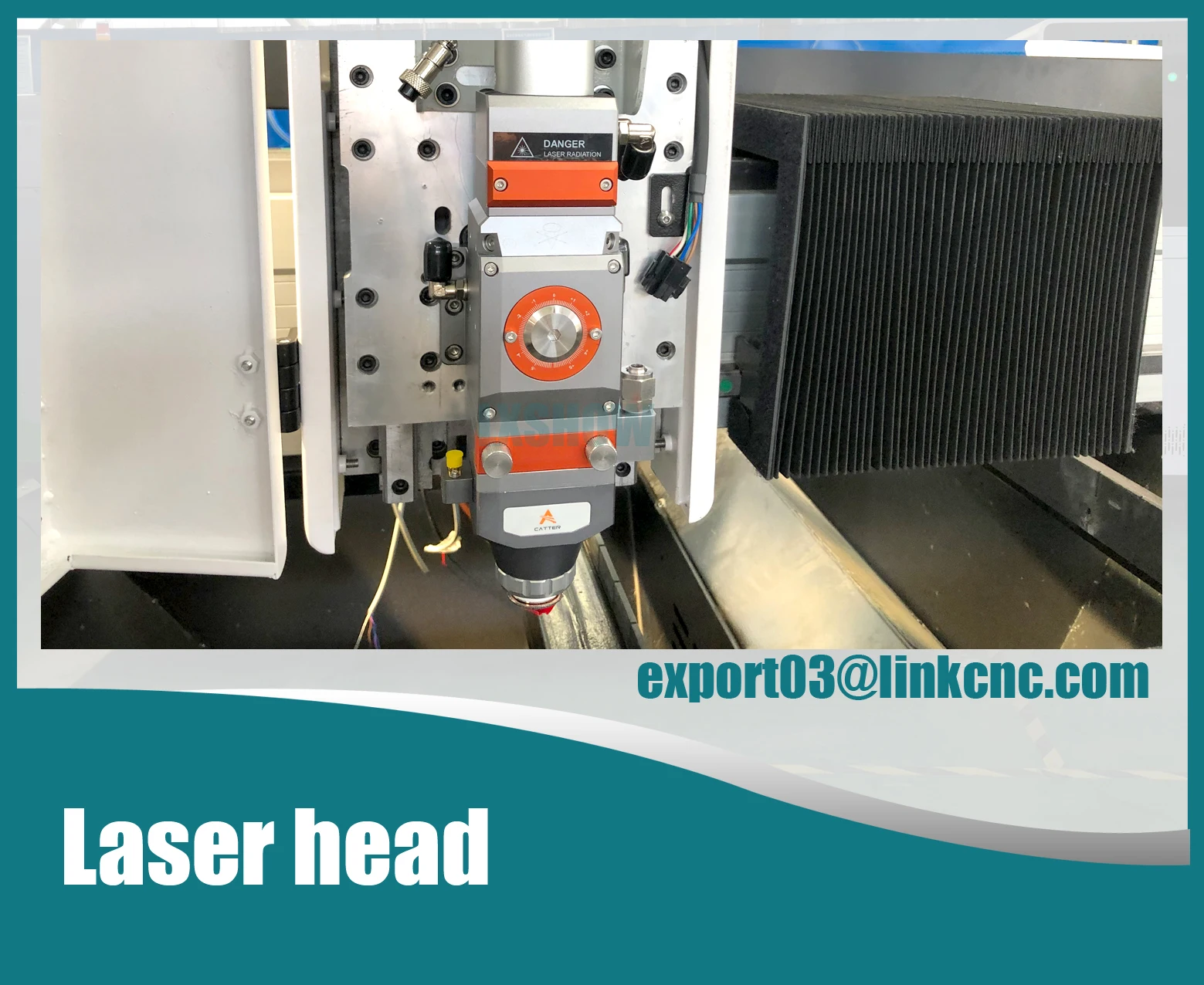

- Laser cutting head: Raytools/WSX

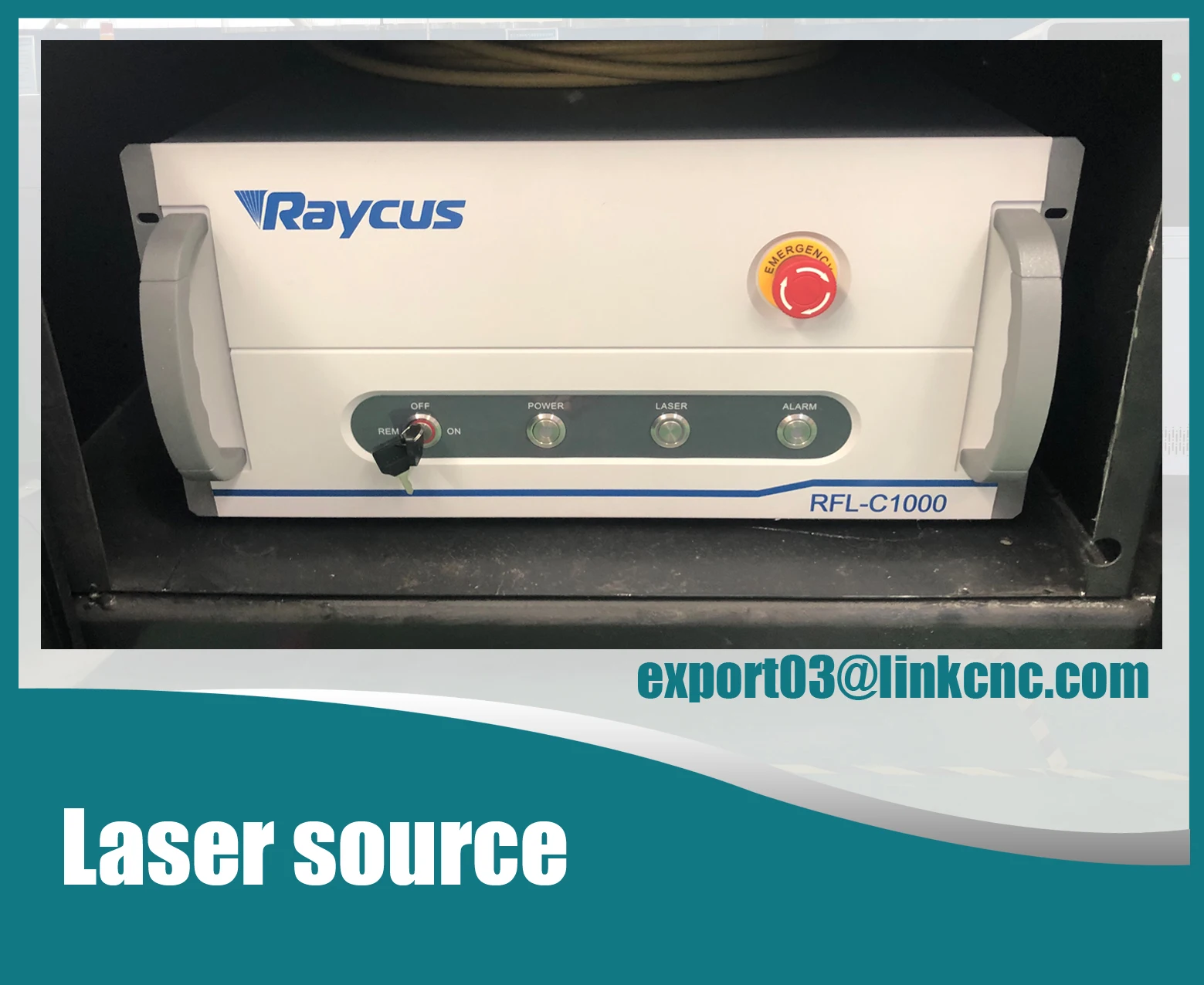

- Laser source: Raycus / IPG

- Servo motor: YASKAWA/Delta

- Controller: Bochu/Au3tech

- Lubrication System: Automatic lubrication

- Guide rail: HIWIN

- Power requirement: 3 phase 380v

- Driving mode: Dual drive

- Software: Cypcut/Au3tech

- Color: White and black(can be customized )

1530 CNC fiber laser cutting machine 500w 1000w

Real machine in the factory:

Why choose us?

| •3 years warranty for machine,2 years for laser source | •Visting arrange |

| •18 hours online after-sale service | •Video call meeting |

| •Free sample test support | •5 days free training in your factory |

Working principle:

Laser cutting is achieved by applying high power density energy generated by laser focusing. Under the control of the computer, the laser is discharged by pulses to output a controlled repetitive high-frequency pulsed laser to form a beam with a certain frequency and a certain pulse width. The pulsed laser beam is transmitted and reflected through the optical path and is focused by the focusing lens group. On the surface of the processed object, minute, high-energy density light spots are formed, and the focal spot is located near the surface to be processed, and the processed material is melted or vaporized at an instant high temperature. Each high-energy laser pulse sputters a small hole on the surface of the object in an instant.Under the control of the computer, the laser processing head and the material to be processed perform continuous relative movement and dotting according to the pre-drawn graphics, so that the object will be processed into The desired shape. The technological parameters (cutting speed, laser power, gas pressure, etc.) and movement trajectory during slitting are controlled by the CNC system, and the slag at the slit is blown off by the auxiliary gas with a certain pressure.

![]() Machine part:

Machine part:

1.Laser Source:Providing the laser from this power supply,it is optional according customer requirement with Raycus,MAX or IPG brand.

2.Industrial PC:Support draw the simple graph on it,low falut than common computer.You could control machine by DSP or it.Preset the cutting track,working on more exact place,saveing the material.

3.Control Box:Independent control box.Driver,main board,THC controller,the power supply of other electrical apparatus element are there.Reasonable and tidy arrangement of the wire will be more easy to find the falut when the machine have any problem.

4.Laser head:Standard manual focus laser cutting head for low power,auto focus laser cutting head for high power.Brand is optional (Au3tech,Raytools,precitec).All have good seal,don’t need to worry the dust will contaminate the lens.Assuring the cutting accurancy.

5.Auto oil lubrication:It could lubricate the rail more well-proportioned than manual lubrication,keep the rail working smooth.

6.Sawtooth table:It could support heavier metal plate than balde table.Reducing the contact area from the metal plate,preventing it cut by laser so that enlength using life.

7.Alarm light:Green for noaml working.Yellow means there are any problem of the power supply.Red means machine stop by emergency.Didfferent light could relect different information immedately.

.

.

Application

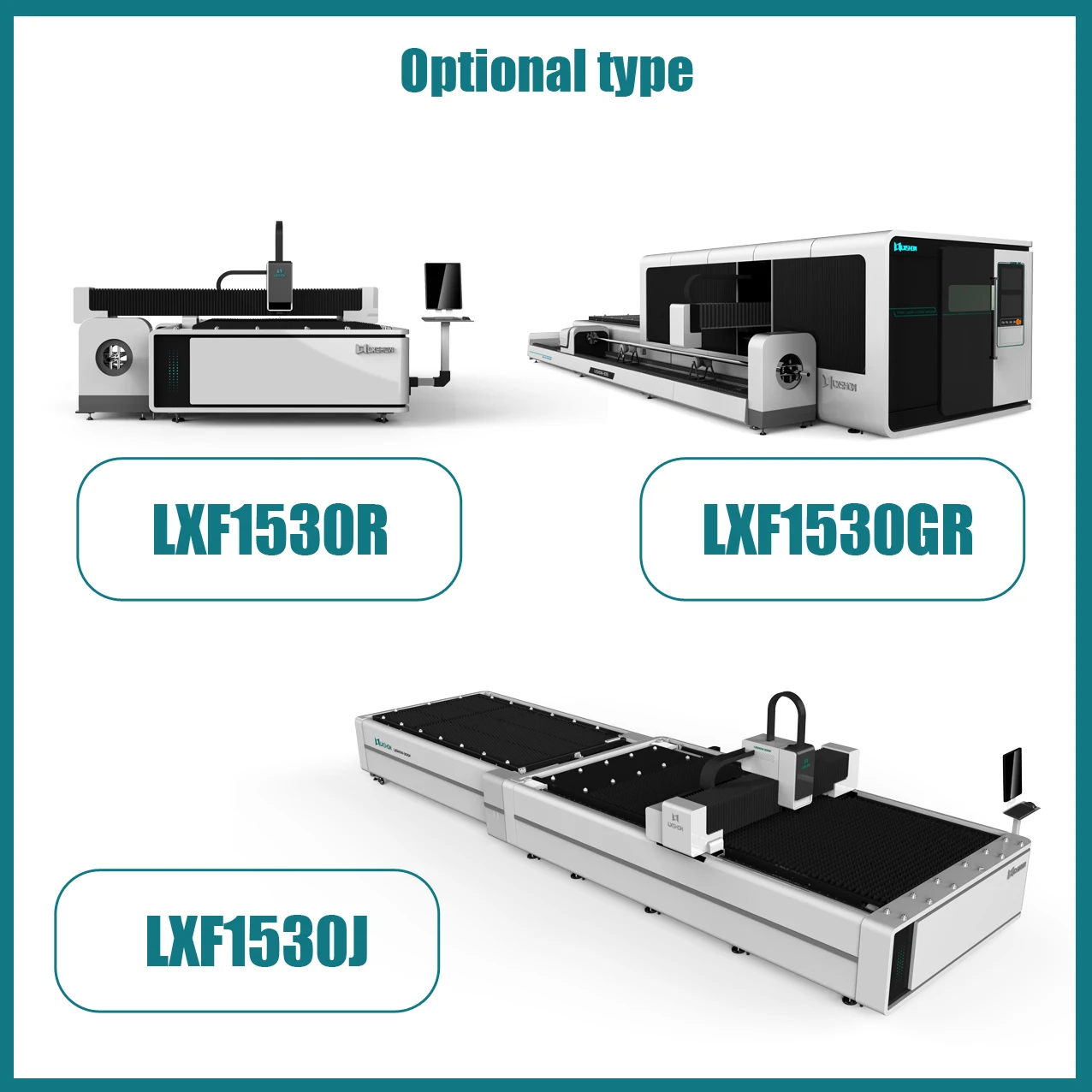

| Fiber laser cutting machine LXF1530 parameter | ||

| 1. | Working area | 1500*3000mm |

| 2. | Power | 500w/750w/1000/1500/2200/3300/4000/6000/8000/12000/25000W |

| 3. | Laser wave length | 1064nm |

| 4. | Transmission system | X Y axis rail transmission,Z axis ball screw transmission |

| 5. | X.Y axis location accuracy | ±0.01mm |

| 6. | X.Y axis repeat location accuracy | ±0.01mm |

| 7. | Max idle speed | 100m/min |

| 8. | Application Material |

Metal sheet Iron/CS/SS/Aluminum/Copper and all kinds metal |

| 9. | Machine size | 4800*2600*1860mm |

| 10. | Net weight | 3800kg |

| 11. | Gross weight | 4000kg |

Customer using feedback video:

Company information:

Our factory has 3 facilities, total area is about 32,000 square meters, 10,000 square meters for fiber laser cutting machine. Another two for CO2 laser and the third one for laser marking/welding/cleaning.

15 years experience for laser machine manufacture,7 years experience for exoporting.Cooperated with more than 200 countries and area.

Customer satisfaction is our most concern point.We will keep to provide the good quality machine and superior service to every customer!

Certification:

We have ISO9001 certification and SGS report verified by TUV, CE and FDA certificattion and some certificates with local honor.

Packing and delivery:

Delivery time:standard 15 days for standard machine,25-40 days for customize machine.

Contact information:

Bernice

Skype: lingxiangcnc3

Web:www.laserlx.com

Email: export03(@)linkcnc.com

Whatsapp:+86 15315133550